Fin style0Straight 1Slot 2Triangle wave 3Sine wave Tube material-1See notes 0Copper 1Steel 2Aluminum Fin material-1See notes 0Aluminum 1Copper 2Steel. Circuits numberNB circuit per row.

The selection process of the evaporators that operate in a system of refrigeration with CO2 is very similar to the selection of evaporators for ammonia.

. Splitting a DX Evaporator coil is one of the toughest concepts to understand in the coil business. Direct Expansion Evaporator An Evaporator or Direct Expansion DX Coil works on the refrigeration effect cooling occurs when a fluid under. Refrigerant flowing through the coil tubes is controlled by a thermostatic-expansion valve.

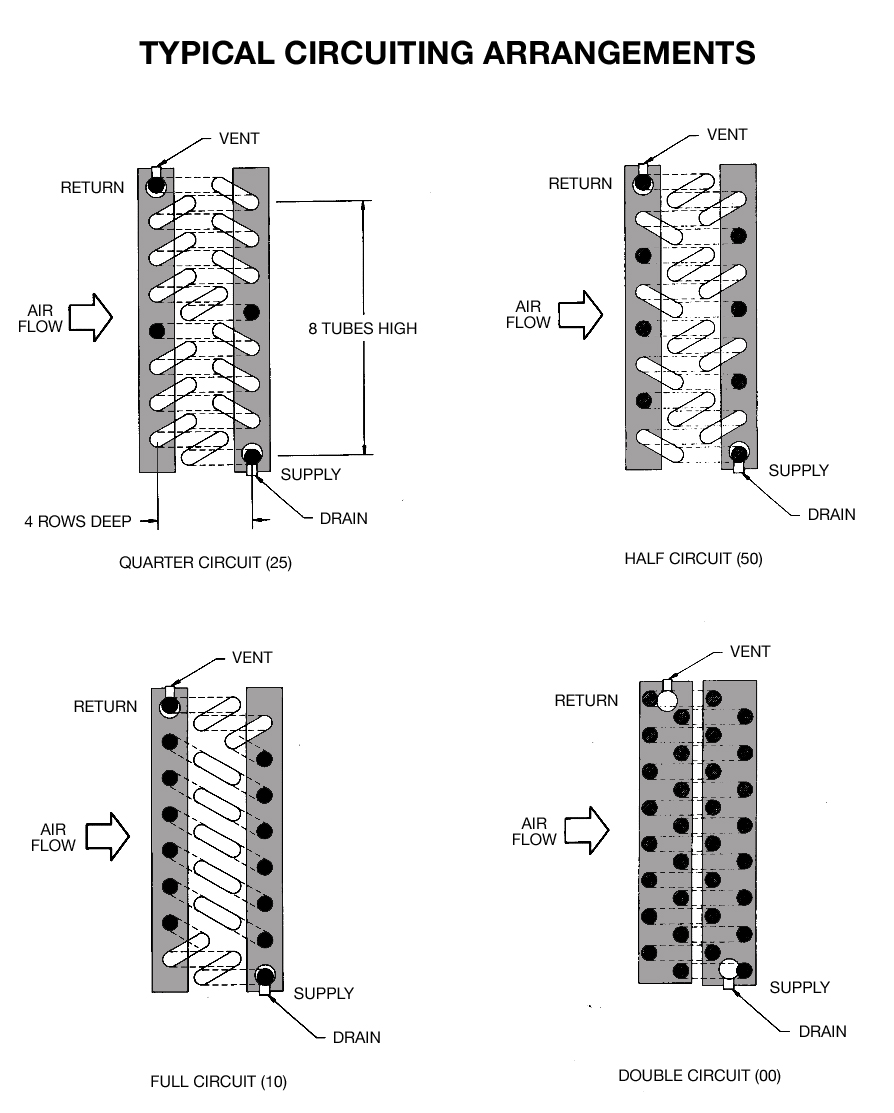

Wide fin spacing availability reduces the affect of frost build up on low temperature applications. The fan-coil unit is frequently used in systems having variable capacities as described above and the evaporator of these units is sometimes provided with a plurality of refrigerant circuits groups of. Evaporator Coil Circuiting Options.

Design of Evaporator with CO2 Coolant. All evaporator coils are counter flow circuited and equipped with pressure type distributors and all distributor tubes are of equal length to assure equal distribution of refrigerant to each circuit. Methods to design the cooling and dehumidifying coil either chilled water coil or Dx evaporator coil are usually based on log mean enthalpy or log equivalent dry-bulb temperature difference 1.

Matches existing dimensions and performance for existing coils. In both methods the cooling coil is treated as a single zoneregion and hence the required surface area is determined 2. The heart of our air heat exchangers is the finned coil built up from a circuit of interconnected tube serpentines and hydrophilic anti-corrosive coated fins to increase the heat exchanging surface.

In the design of evaporator coils increasing refrigerant mass velocity can enhance the heat transfer of an evaporator coil. Coil arrangement 0In-line 1Cross. Designed for use in comfort cooling process cooling and refrigeration Coilmaster evaporator coils are proven for use with all of todays refrigerants.

Evaporator coil also called the evaporator core is the part of an air conditioning system where the refrigerant absorbs heat. Evaporator Like the condensing unit evaporator coils also have performance curves Figure 2. Splitting the coil simply means that 2 compressors can operate off of the same coil.

Ambient design is 95F then the SST of the condensing unit must be 45F. Initial evaporator widthLD mm. Wide fin spacing availability reduces the affect of frost build up on low temperature applications.

The fan-coil unit includes an evaporator which absorbs heat from air passing therethrough and a fan moving the air through the evaporator. That is its where the cold air comes from. Pounders Marine Diesel Engines and Gas Turbines Tenth Edition 2021.

Direct-expansion evaporator coils are used in low temperature refrigeration applications to cool and sometimes dehumidify air. This manner of the cooling coil design could lead to an. Knowledge there is not an existing distributed simulation model for the study of tube circuitry of evaporator coils.

This differential is created and maintained compressor and performs several important functions. Our proprietary circuiting provides for optimal system performance at minimal air-side and refrigerant pressure drops. For applications including comfort and process cooling dehumidification energy reclamation and more.

That is its where the cold air comes from. Our proprietary circuiting provides for optimal system performance at minimal air-side and refrigerant pressure drops. Unique interlaced circuiting options assure uniform refrigerant distribution over the entire face area of the coil.

Coil geometry fins rows height length etc. Custom design for new applications. Which are usually based on log mean enthalpy or log equivalent dry-bulb temperature difference.

Circuiting for face control and row control is also available as standard on a wide variety of coils. For use in central systems or duct applications. A new modeling procedure for circuit design and performance prediction of evaporator coils using CO2 as refrigerant By zine aidoun Modelling Fin-and-Tube Gas-Cooler for Transcritical Carbon Dioxide Cycles.

Evaporator manufacturers commonly require the same data for both refrigerants and likewise performance and selection data will be displayed in the. Focuses on Methods to design the cooling and dehumidifying coil or Direct Expansion evaporator coil. Designed for use in comfort cooling process cooling and refrigeration Madok evaporator coils are proven for use with todays refrigerants.

To avoid this evaporator coils come with distributors. The Product Evaporator circuit consists of an insulated pipe an evaporator valves a single wall pipe and sensors. The distributor is ideally mounted pointing up or down to minimize this liquidgas separation it blends these two fluids and evenly distributes this stream to.

RowsNL along air flow. The evaporator curves are plotted as capacity tons versus SST and are based on two fixed factors. The heat transfer capabilities of the evaporator coil.

Air passing across the fins is cooled as the refrigerant flowing through the tubes absorbs heat and is boiled evaporated. Unique interlaced circuiting options assure uniform refrigerant distribution over the entire face area of the coil. Evaporator refrigerant circuit in the passage that exists between the inlet and outlet of the evaporator.

Evaporator Coils Single dual or quad compressor circuits allow precise capacity control. To refrigerant mass flow through the evaporator pressure drop must be created between the inlet and outlet ports. Duplication of obsolete coils.

One obvious advantage or reason that you might split a DX coil is that you can shut down 1 of the compressors when the cooling load does not require it. EJ Model Type EJ Figure 4 coils come with interlaced circuiting. All sizes shapes capacities circuit patterns and fintube configurations.

This form of capacity control. Single dual or quad compressor circuits allow precise capacity control. With an air evaporator coil commonly used in low temperature supermar- velocity of 1 ms 35 of their total length was used in the quality kets applications.

The coil configuration selected consisted in a range 0751 while only 175 was used in the quality range of parallel-counter current combination of two circuits and the 0025. A variety of load-split options provides the flexibility designers need to optimize the system not only at design conditions but. In aadition to create a refrigerant to flow through to die.

The heart of our air heat exchangers is the finned coil built up from a circuit of interconnected tube serpentines and hydrophilic anti-corrosive coated fins to increase the heat exchanging surface. However this will increases the pressure drop in the refrigerant side and performances of the. Bruce Nelson President Colmac Coil.

Evaporator coil also called the evaporator core is the part of an air conditioning system where the refrigerant absorbs heat.

The Benefits Of Intertwined Circuiting In Split Coils Fabtech

Understanding Coil Circuiting With A Simple Guide Campbell Sevey

Chilled Water Cooling Coils Circuiting Made Easy

Evaporator Coils Madok Manufacturing Inc

0 comments

Post a Comment